What Is Volumetric Filling Machine?

A volumetric filling machine is a type of filling machine that is used to fill containers with a specific volume of liquid or other substance. This type of filling machine typically uses a combination of sensors, valves, and other components to accurately measure and dispense the desired volume of material into a container. The exact mechanism and design of a volumetric filling machine can vary depending on the specific application, but they are commonly used in a wide range of industries, including food and beverage, pharmaceutical, and chemical manufacturing.

Which Industries Use Volumetric Filling Machine?

Volumetric filling machines are commonly used in a variety of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals. These machines are designed to accurately dispense a specific volume of product into containers of various shapes and sizes. They are often used to fill bottles, cans, jars, and other containers with liquids, pastes, powders, or other types of product.

How The Volumetric Filling Machine Works

A volumetric filling machine is a type of automated machine that is used in packaging to dispense precise amounts of product into containers. The machine works by using a series of mechanical and pneumatic components to measure and dispense the product into containers that are transported along a conveyor belt.

The process begins when the containers are placed onto the conveyor belt and are transported to the filling station. At the filling station, the containers are positioned underneath the filling nozzles, which are connected to a product hopper. The hopper is filled with the product that needs to be dispensed, and the machine is programmed to dispense a precise amount of product into each container.

Once the containers have been filled with the product, they are transported to the sealing station, where the containers are sealed to prevent the product from spilling or leaking. The sealed containers are then moved to the labeling and packaging station, where they are labeled and packaged for shipping or storage.

The volumetric filling machine is a highly accurate and efficient way to dispense product into containers. It can be used in a variety of industries, including food and beverage, pharmaceutical, and chemical, to accurately and quickly package products.

What Are The Advantages Of Using A Volumetric Filling Machine?

There are several advantages to using a volumetric filling machine, including:

High accuracy and precision: Volumetric filling machines use precise measurements to dispense liquids or other materials into containers, ensuring that each container is filled to the same level with the same amount of material. This is especially important in industries such as pharmaceuticals, where precise measurements are critical.

Speed and efficiency: Volumetric filling machines are designed to fill containers quickly and efficiently, which can help to increase productivity and reduce labor costs.

Flexibility: Many volumetric filling machines are capable of filling a variety of container sizes and shapes, which makes them suitable for use in a wide range of industries.

Easy to use: Volumetric filling machines are typically easy to operate, requiring minimal training to use effectively.

Cost-effective: Because they are designed to be accurate and efficient, volumetric filling machines can help to reduce waste and minimize the use of materials, which can save money in the long run.

What Are The Main Parts Of Volumetric Filling Machine?

A volumetric filling machine typically has several main components, including a container handling system, filling nozzles, a dosing system, and a control system. The container handling system is responsible for moving containers through the filling machine and positioning them under the filling nozzles. The filling nozzles are used to dispense the product into the containers, and the dosing system controls the amount of product that is dispensed. The control system manages the overall operation of the filling machine and may include a user interface for inputting filling parameters and monitoring the machine's performance. Other components of a volumetric filling machine may include sensors, conveyors, and packaging equipment.

What Are The Types Of Volumetric Filling Machine?

Volumetric filling machines are a type of liquid filling machine that are commonly used in the food, beverage, and chemical industries to accurately and efficiently fill containers with a specific volume of liquid. These machines use a variety of different technologies to measure and dispense the liquid, and can be divided into several different types based on the specific method they use. Some common types of volumetric filling machines include:

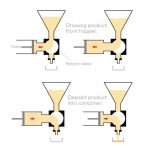

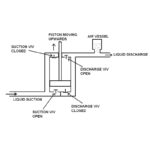

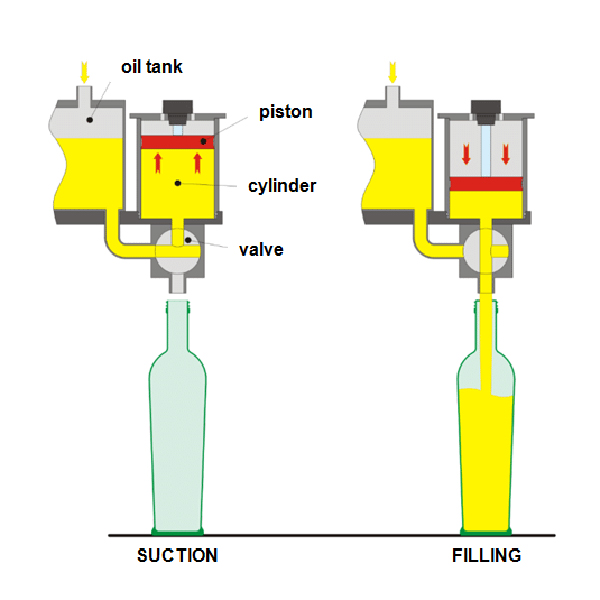

Piston filling machines:

These machines use a piston to dispense a specific volume of liquid into a container. The piston is typically controlled by a servo motor or a hydraulic system, which allows the operator to adjust the filling volume as needed.

Gravity filling machines:

These machines use the force of gravity to dispense liquid into containers. The liquid is typically placed in a hopper or tank above the filling nozzle, and the weight of the liquid causes it to flow into the container.

Time-based filling machines:

These machines dispense liquid for a specific amount of time, rather than measuring the volume of liquid being dispensed. The filling time is typically controlled by a timer or a PLC (programmable logic controller), which allows the operator to adjust the filling time as needed.

Weight-based filling machines:

These machines use a load cell or other type of weight sensor to measure the weight of the liquid being dispensed. The filling volume is then calculated based on the weight and the density of the liquid.

Each of these types of volumetric filling machines has its own advantages and disadvantages, and the best type of machine for a particular application will depend on the specific requirements and constraints of the filling process.

What Are The Features Of The Volumetric Filling Machine?

A volumetric filling machine is a type of packaging equipment that is used to fill containers with a specific volume of product. Some of the key features of a volumetric filling machine may include:

Adjustable filling volumes:

Most volumetric filling machines are designed with the ability to adjust the filling volume to accommodate different container sizes and product quantities.

Multiple filling nozzles:

Many volumetric filling machines come equipped with multiple nozzles, which allows them to fill multiple containers simultaneously and increase the overall filling speed.

High accuracy:

Volumetric filling machines are known for their high level of accuracy when it comes to filling containers with a specific volume of product.

Sanitary design:

Many volumetric filling machines are designed with food safety and sanitation in mind, with features such as easy-to-clean surfaces and enclosed filling mechanisms to prevent contamination.

Automatic operation:

Many volumetric filling machines are designed to operate automatically, with the ability to fill containers, cap them, and label them without the need for manual intervention.

Versatility:

Volumetric filling machines are often designed to handle a wide range of products, including liquids, powders, and pastes, making them a versatile option for many different types of packaging operations.

How To Choose Volumetric Filling Machine?

There are a few key factors to consider when choosing a volumetric filling machine. Here are some tips to help you make the right decision:

Consider your product:

Different filling machines are designed for different products, so it's important to choose a machine that is suitable for your specific product. For example, if you are filling a liquid product, you will need a different machine than if you are filling a dry, granular product.

Consider the size of your operation:

The size of your operation will determine the type of filling machine you need. For small operations, a manual or semi-automatic filling machine may be sufficient, but for larger operations, a fully automatic machine may be necessary.

Consider the accuracy and precision of the machine:

The accuracy and precision of the filling machine is important because it will determine the quality of your final product. Look for a machine that offers high-precision filling, as well as the ability to adjust the filling volume to suit your specific needs.

Consider the speed of the machine:

The speed of the filling machine is another important factor to consider. If you have a large volume of products to fill, you will need a machine that can fill containers quickly and efficiently.

Consider the machine’s durability and maintenance requirements:

Filling machines can be expensive, so it's important to choose a machine that is durable and will last for a long time. Look for a machine that is made from high-quality materials and that has a good reputation for reliability. Additionally, consider the maintenance requirements of the machine, as regular maintenance is essential for ensuring that the machine continues to operate at peak performance.

Which Containers Can Be Filled By Volumetric Filling Machine?

A volumetric filling machine is a type of filling machine that is used to fill containers with a specific volume of liquid. The type of containers that can be filled by a volumetric filling machine will depend on the size and design of the machine itself, as well as the specific requirements of the product being filled. Some common types of containers that can be filled by a volumetric filling machine include bottles, cans, and jars. These containers can be made of various materials, including glass, plastic, and metal. It is important to note that some volumetric filling machines may be designed to handle only certain types of containers, so it is always best to check with the manufacturer or supplier to ensure that the machine is capable of filling the specific type of container you are using.

Volumetric Filling Machine Vs Level Filling Machine

A volumetric filling machine and a level filling machine are two different types of machines used for filling containers with liquid or other types of materials.

A volumetric filling machine is a type of filling machine that uses precise volume measurements to fill containers with a specific amount of liquid or other material. This type of filling machine is commonly used in industries where precise filling is important, such as in the pharmaceutical and food and beverage industries.

A level filling machine, on the other hand, is a type of filling machine that uses a level sensor to fill containers with liquid or other materials until a certain level is reached. This type of filling machine is commonly used in industries where the precise volume of the product being filled is not as important, such as in the cosmetic and household chemical industries.

Both volumetric and level filling machines are widely used in various industries for filling containers with liquids and other materials. The type of filling machine that is used will depend on the specific needs and requirements of the industry and the product being filled.

How To Clean The Volumetric Filling Machine?

To clean a volumetric filling machine, follow these steps:

- Disconnect the machine from its power source and any other equipment it may be connected to.

- Remove any containers or packaging materials from the machine.

- Use a soft cloth or brush to gently clean the exterior of the machine, paying special attention to any nooks and crannies where debris may have accumulated.

- Use a mild detergent or cleaning solution to clean the interior of the machine, including the filling nozzles and other parts that come into contact with the product being filled.

- Rinse the machine thoroughly with water to remove any residue from the cleaning solution.

- Dry the machine thoroughly with a clean cloth or towel.

- Reassemble the machine and reconnect it to its power source and any other equipment it was previously connected to.

- Test the machine to ensure it is operating properly before resuming normal use.

It's important to clean your volumetric filling machine regularly to prevent contamination and ensure that the machine is operating at peak efficiency. Cleaning the machine thoroughly after each use is the best way to maintain its performance and extend its lifespan.