What are viscous liquids?

Viscous liquids are thick and sticky, and they have a high resistance to flow. Examples of viscous liquids include honey, jam, peanut butter, mayonnaise, and ketchup. These liquids are difficult to handle and require specialized equipment to be filled accurately and efficiently.

How do viscous liquid filling machines work?

Viscous liquid filling machines use a variety of technologies to fill containers with viscous liquids. Some machines use gravity filling, where the liquid is poured into the container from a hopper or tank located above the filling area. Other machines use a piston or plunger to dispense the liquid into the container, while others use a nozzle or tube to fill the container.

Regardless of the technology used, the basic process of filling a container with a viscous liquid is the same. First, the container is placed in the filling area and aligned with the filling mechanism. Then, the liquid is dispensed into the container, either by gravity or through a piston, nozzle, or tube. The filling process is typically controlled by a computer or other electronic system, which ensures that the correct amount of liquid is dispensed into each container.

What are the different types of viscous liquid filling machines?

There are several different types of viscous liquid filling machines, each of which uses a different technology to fill containers with viscous liquids. The most common types of viscous liquid filling machines are:

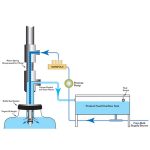

Gravity filling machines:

These machines use the force of gravity to dispense viscous liquids into containers. The liquid is poured into the machine from a hopper or tank located above the filling area, and it flows into the container under the force of gravity. Gravity filling machines are typically used for low-viscosity liquids and are not suitable for very thick or sticky liquids.

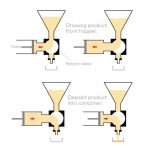

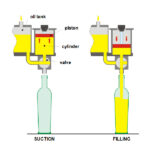

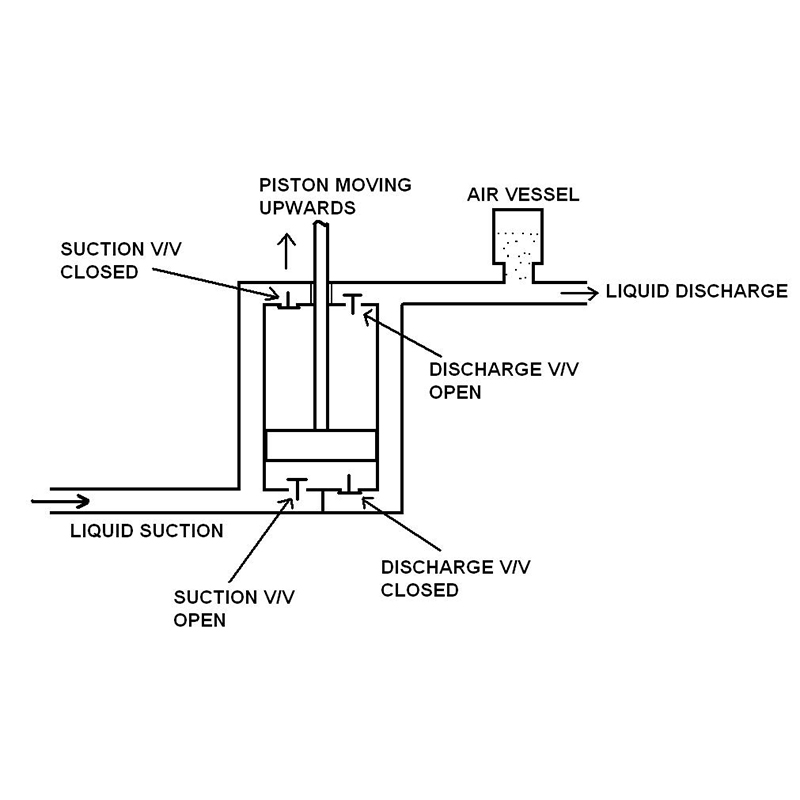

Piston filling machines:

These machines use a piston or plunger to dispense viscous liquids into containers. The piston is driven by a motor or other power source, and it forces the liquid out of the machine and into the container. Piston filling machines are typically used for medium- to high-viscosity liquids and are capable of filling containers with very thick or sticky liquids.

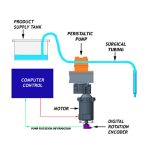

Pump filling machines:

These machines use a pump or tube to dispense viscous liquids into containers. The nozzle is typically located inside the container, and the liquid is forced through it by a piston or other mechanism. Pump filling machines are typically used for high-viscosity liquids and are capable of filling containers with very thick or sticky liquids.

What are the advantages and disadvantages of viscous liquid filling machines?

Viscous liquid filling machines have several advantages over other types of filling equipment. Some of the main advantages of viscous liquid filling machines include:

Improved accuracy:

Viscous liquid filling machines are typically equipped with electronic controls that ensure that the correct amount of liquid is dispensed into each container. This allows for more accurate filling and reduces the amount of waste.

Increased speed:

Viscous liquid filling machines are designed to fill containers quickly and efficiently. This can help to increase the overall speed of the filling process and improve productivity.

Reduced labor costs:

Viscous liquid filling machines are typically automatic, which means that they can be operated by a single person. This can help to reduce labor costs and free up workers for other tasks.

Improved product quality:

Viscous liquid filling machines are designed to fill containers with high accuracy and consistency. This can help to improve the overall quality of the product and reduce defects.

Despite these advantages, there are also some disadvantages to using viscous liquid filling machines. Some of the main disadvantages include:

High initial cost:

Viscous liquid filling machines are typically more expensive than other types of filling equipment. This can be a barrier for small businesses or those on a tight budget.

Limited versatility:

Viscous liquid filling machines are designed specifically for viscous liquids, so they may not be suitable for other types of products. This can limit the range of products that can be filled using a viscous liquid filling machine.

Maintenance requirements:

Viscous liquid filling machines are complex pieces of equipment, and they require regular maintenance and cleaning to ensure that they continue to operate effectively. This can be time-consuming and costly.

How to choose the right viscous liquid filling machine for your needs

When choosing a viscous liquid filling machine, there are several key factors to consider. These include:

The viscosity of the liquid:

The viscosity of the liquid will determine the type of viscous liquid filling machine that is suitable for your needs. For low-viscosity liquids, a gravity filling machine may be sufficient, while for high-viscosity liquids, a piston or nozzle filling machine may be necessary.

The size of the containers:

The size of the containers that need to be filled will determine the size and capacity of the viscous liquid filling machine. Make sure to choose a machine that can accommodate the size and shape of the containers you will be using.

The speed of the filling process:

The speed of the filling process is an important factor to consider when choosing a viscous liquid filling machine. If you need to fill a large number of containers in a short amount of time, a faster machine may be necessary.

The accuracy of the filling process:

The accuracy of the filling process is another key factor to consider when choosing a viscous liquid filling machine. Make sure to choose a machine that is capable of filling containers with high accuracy and consistency to reduce waste and improve product quality.

The maintenance requirements:

Viscous liquid filling machines require regular maintenance and cleaning to ensure that they continue to operate effectively. Make sure to choose a machine that is easy to maintain and clean to minimize downtime and maximize productivity.

In conclusion, a viscous liquid filling machine is a specialized piece of equipment used for filling containers with viscous liquids. Viscous liquids are thick and sticky, and they require specialized equipment to be filled accurately and efficiently. There are several different types of viscous liquid filling machines, each of which uses a different technology to fill containers with viscous liquids. Viscous liquid filling machines have several advantages, including improved accuracy, increased speed, and reduced labor costs. However, they also have some disadvantages, including a high initial cost and limited versatility. When choosing a viscous liquid filling machine, it is important to consider the viscosity of the liquid, the size of the containers, the speed and accuracy of the filling process, and the maintenance requirements.