What is an Overflow Filler?

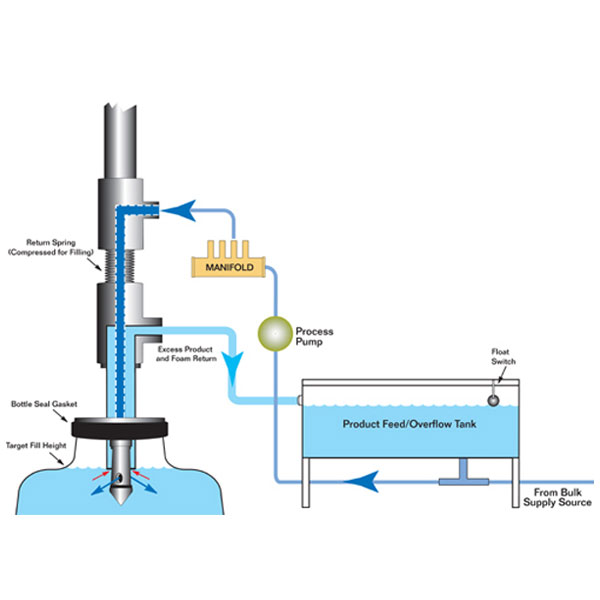

An overflow filling machine is a unique piece of packaging equipment that fills every bottle to the same level, regardless of the interior volume of the individual containers. Rather than filling by volume or weight, the overflow filler uses a nozzle that, once liquid reaches a certain level in the container, overflows product back into a holding tank. By creating a seal over the bottle and allowing product to recirculate, the overflow filler creates a unique fill to level system.

The unique nozzle of the overflow filling machine can be used to create both semi-automatic and automatic bottle fillers, with the principle being the same for either level of automation. As nozzles dive down in to the bottles, a nozzle seal covers the bottle opening to prevent leaks or spills, sealing the container for the duration of the fill. Spacers are used on the nozzle itself to achieve the desired level for the fill in the bottle. These spacers are made to be easily adjustable on each nozzle to allow for adjustments to the fill levels. Along with easily adjustable height and nozzle width, one overflow filler can typically handle a wide range of bottle shapes and sizes.

The obvious advantage of the fill-to-level system is a machine that allows products packaged in clear containers to have a consistent appearance when on the shelf. Items such as bottled water, distilled spirits, window cleaners and more, benefit in appearance and build consumer trust when each container appears filled to the same level with the same amount of product. In addition, the overflow filler is a great way to consistently and reliably fill products that foam. As products - think soap - foam in the bottle during the fill, the overflow basically allows liquid to continue to flow into, and overflow out of, the bottle until the foam is eliminated.

Overflow Filling Machine Principle

Overflow Filling Machines are used to fill a wide range of water-thin to low-viscosity liquids into most containers. Overflow Fillers provide the same cosmetic fill level, making them ideal for filling transparent containers that must have a consistent fill level.

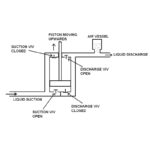

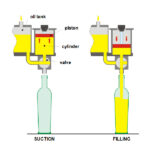

The supply side (dark blue) of a two-part nozzle is used to pump product into the container. When the container fills up to the target fill height, the excess product and foam are forced out of the container (red arrows) via the return side to the original product source tank.

Application:

This type of filler is best suited for liquids with low to medium viscosity. liquids with solid particulates not exceeding 1/16″ can also be filled. Note that overflow fillers are the machine of choice in handling very foamy products at higher speeds.

Examples:

Sauces, syrups, light gels and shampoos, foamy cleansers and chemicals, water and other non-carbonated aqueous beverages.

Advantages:

High performance, easy to clean, easy to operate, expandable at low cost. Offers the greatest flexibility at the lowest cost,

Bottle requirements for overflow filling machine

When bottles are manufactured, an attempt is made to keep the process as consistent as possible for obvious reasons. Most packagers want each and every container to look similar to help boost shelf appeal and even small inconsistencies may not be identifiable using the naked eye. However, when liquids are added to bottles with slight variations in interior volume, the visible fill level can vary, even though the same amount of product is present in each container. The overflow filling machine is used to combat these inconsistencies in volume by filling each and every bottle to the same exact level, regardless of interior volume.

Overflow fillers achieve this level fill by using a unique nozzle that not only seals over the bottle opening, but allows product to flow back through the nozzle to the holding tank or reservoir, thus eliminating product waste as well. As the nozzle seals over the bottle, the fill port is opened, allowing product to enter the bottle. Once the product reaches the specified level in the container, controlled by using spacers on each of the fill heads, the product exits the bottle via the return port, "overflowing" out of the bottle and back into the tank or reservoir. This principle can be used for free-flowing products in containers both large and small, though great variations in size may require different nozzle sizes for efficiency purposes.

As noted above, the level fill can mean that the actual volume of product will vary from container to container. While this can be a concern to industries such as distilled spirits, pharmaceuticals and others with volume requirements, almost all industries will have a target volume along with an acceptable range. In most cases, the change in interior volume will be so slight that the danger of falling outside of the acceptable range is nearly non-existent. However, packagers with this concern will want to check with their bottle manufacturers to ensure that interior volume will not vary greatly and may want to (or even be required to) include some type of quality control check in their own packaging process.

Benefits & Disadvantages

Benefits of overflow filler

- It can be used to fill small bottles.

- This machine can handle numerous ranges of thin, free-flowing and other liquids with medium viscosity.

- The machine performs very efficiently.

- Since the liquids it can fill have low and medium viscosity, the rate of filling these products is relatively high.

- It is easy to clean and maintain.

- This machine is easy to operate.

- Machine is cost-effective. The machine can be manipulated to fill and cap numerous products at a very low cost.

- It is ideal for foamy products since it operates on a closed-loop basis.

Disadvantages of overflow filler

- This machine isn’t good for products with a viscosity of more than 25,000 centipoises or more than 1/16 inches particulates.

- It is also not very ideal for filling large containers.

Overflow Filling Equipment works on the principle of filling to a level inside a container. Even when the internal volume of a container may vary slightly, the special nozzles used on these filling machines ensure that each and every container reach the same level. Overflow fillers are ideal for thin to medium viscosity products and work especially well with products that foam.

Overflow filling machines are an ideal solution for glass and other clear containers, like a typical 750ml distilled spirits bottle or clear plastic beverage bottles. By filling to a level, this type of bottle filler insures an even, consistent finish, perfect for shelf display.

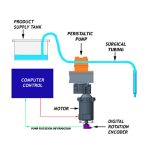

Automatic Overflow Fillers from VKPAK are ideal for thin to medium viscosity liquid products, including products that are "foamy" by nature. The automatic overflow filling machine is manufactured to be a part of a complete, automated inline packaging system and can be integrated into just about any existing packaging line. This liquid filler also adds aesthetic value to products packaged in clear glass or plastic containers by filling to a level with each cycle run.