VK-FF Automatic Corrosive Liquid Filling Machine

VK-FF Corrosive Liquid Filling machine is specially developed for the low viscosity but corrosive liquid filling. The whole machine is controlled by Schneider PLC, which can realize the precise filling, stable performance and easy parameter setting. Pneumatic part adopts AirTAC brand to ensure long-term stable operation. It is application for filling Acid, alkali materials, highly corrosive pesticides, 84 disinfectant, toilet cleaner, iodine, etc.

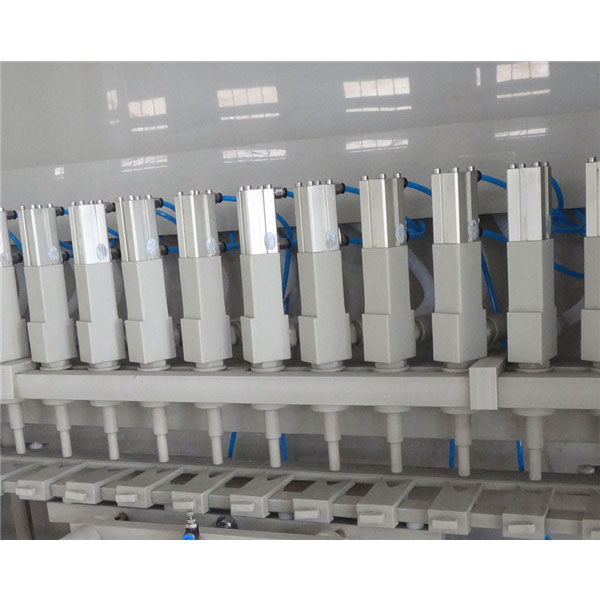

The machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 6/8/10/12/16 /20 heads.

The filling volume is controlled by filling time, with weight feedback of each filling nozzle to PLC to assure good filling accuracy.

All product contact parts is made with strong plastic material to avoid corrosion.

Description

Corrosive products are dangerous to personnel and accelerate depreciation of capital equipment. Therefore, it is paramount that a filling machine design for these types of products control exposure of personnel to hazardous liquids and gasses. It is also important that materials of construction and other special design features be chosen to protect the buyer’s investment. There are many examples of tragic accidents due to the lack of foresight in this regard. Moreover, machines not correctly built for these environments see major disrepair and decay of the machinery within 6 months.

Generally speaking, the time gravity filling machine is predominant in the corrosive chemical filling industry because of its simplicity of operation and the fact that it does not pressurize or recirculate these chemicals which can increase risk of exposure to personnel. Because the filling machine is used for corrosives that generally attack metal components, there are special design considerations for both materials of construction as well as fasteners in this time gravity filling machine.

If your business deals with filling corrosive liquids into containers, you understand the challenges that can come with finding machinery that can accommodate those liquids. At VKPAK, we are proud to offer corrosive filling machinery, including a corrosion resistant corrosive liquid filling machine. Our corrosive fillers, machined out of HDPE (high density polyethylene), are designed to handle the harsh punishment that comes along with corrosive liquids. The fillers are capable of handling a variety of viscosities, perfect for accommodating a number of different industries’ products.

Automatic corrosive liquid filling machine is engineered to withstand harsh liquid and environments. Each filling machine is built from corrosive resistant plastic material custom to tolerate the corrosive environments and suited to the products they intended for including not only chemical plants producing strong acid or bleach but also food plants using brine or sugar solutions in their products. In both cases, even the factory air alone contributes to the accelerated degradation of the machinery.

- 1. All the machine material are constructed by PVC to anti corrosive including the conveyor, control box.

- 2. Schneider PLC control, and Schneider touch screen operation, it is easy for changing size or modifying parameters.

- 3. Pneumatic elements are all imported, stability and reliability.

- 4. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

Packaging Type: Bottles, Cans

Packaging Material: Paper

Type: Filling Machine

Condition: New

After-sales Service Provided: Online support, Video technical support, Free Spare Parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

Place of Origin: Shanghai, China

Brand Name: VKPAK

Voltage: 220V or 380V

Application: Beverage, Chemical, Food

Weight: 600KG

Certification: CE ISO9001

Driven Type: Pneumatic

Dimension(L*W*H): 2250*1150*1650mm

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Food & Beverage Shops, Advertising Company

Model: VK-FF Corrosive Liquid Filler Automatic Bleach Filling Machine

Function: Automatic Filling Chemical bleach into bottle

Material: Lotion ,Shampoo ,bleach liquid , chemical liquid

Filling Speed: 1000bottle-5000bottle/hour

Volume: 100ml-1000ml and 1000ml-5000ml

Equipment Accommodations For Acids And Corrosives

Corrosion-resistant machines are made from HDPE, and are designed to be able to stand up to the harsh environment that corrosive liquids create. Where standard metal components would normally dissolve, these machines are designed to withstand the chemical reaction. Corrosive-compatible machinery can be used with products such as:

- Cleaning products

- Chemicals

- Bases such as sodium hypochlorite

- Acids including hydrochloric acid

- Water-thin and foaming corrosive liquids

- Pool chemicals

What Makes Corrosive-Resistant Machinery Different?

The standards for machinery that corrosives will pass through are different than the standards for regular machinery. For instance, corrosive-resistant equipment is made with Kynar or Teflon fill valves, HDPE construction, braided PVC tubing, polypropylene fittings, optional enclosures for ventilation and safety, and more. These machines are made with robust materials that hold up against corrosive environments, so you can rely on them to get the job done, time after time.

Technical Parameter

| Model | VK-FF automatic gravity Filling machine(corrosive liquid) | |||||

| Nozzles | 6 | 8 | 10 | 12 | 16 | 20 |

| Idea Filling range | 100-1000ml, 500-5000ml | |||||

| Application bottles | Round , flat or regulars bottles | |||||

| Capacity Per 1000ml | 24bottles/min | 32bottles/min | 40bottles.min | 48bottles/min | 64bottles/min | 80bottles/min |

| Power supply | 220V,50hz | |||||