VK-EPF Automatic Economic Piston Filling Machine

The VK-EPF Economy automatic filling machine is design on the base of the VK-PF, it is also an extremely flexible filler capable of filling accurately and rapidly thin and middle viscosity liquids.

The VKPAK automatic linear piston filler is manufactured with a 304 stainless steel frame and is capable of supporting 2 to 4 fill nozzles PLC Controls, touch screen, food grade contact parts, stainless steel and anodized aluminum construction, plus many more features come standard.

It adds efficiency to any production line used in the cosmetic, food industry, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments

Quick Details

Packaging Type: Bottles

Packaging Material: Paper, Plastic, Wood

Type: Filling Machine

Condition: New

After-sales Service Provided: Online support, Video technical support, Free Spare Parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

Place of Origin: China

Brand Name: VKPAK

Voltage: 220V

Application: Food, Beverage, Commodity, Chemical

Weight: 300KG

Automatic Grade: Automatic

Driven Type: Electric

Dimension(L*W*H): 1200X1250X1700MM

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Model: VK-EPF

Machine name: economic bottle filling machine

Material: Stainless Steel

Capacity: 1000-1500 bph

Filling material: Flowing Liquid

Machine type: Automatic

Packing material: Wood Packing

It is economic filling machine,low cost and high speed.

It suitable for filling liquid such as Shower gel, hand soap, shampoo.

Main Features:

- 1, 304 Stainless steel construction and the liquid contact parts are 316 L stainless steel.

- 2, Pneumatic components and electrical products for famous brand products.

- 3, PLC and touch screen control, convenient parameter setting.

- 4, Accurate filling volume, within ±0.2 for 1000 ML.

- 5, No bottle ,no fill, automatic warning on errors.

- 6, The filling blocked nozzles are anti drops, silk, and auto cut viscous liquid.

- 7, Easy to maintain, no special tools are required.

- 8, Diving nozzles for bottom up filling of foaming products.

- 9, Bottle mouth can be located.

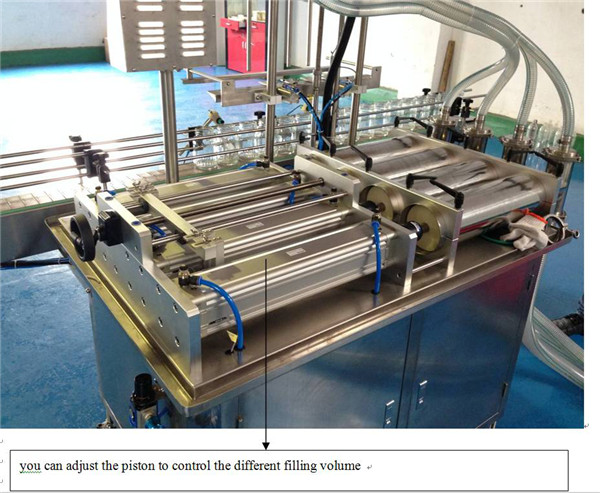

2 Nozzles Economic Filling Machine

Model: VK-EPF-2

Filling Nozzles: 2 Nozzles

Material density: 0.6-1.5

Tolerance of filling quantity(accuracy): ±0.2%

Filling speed:600-1000 bottles/hour

Power: 0.5KW

Voltage: 220V,380V,50HZ/60HZ

Air Pressure: 0.6Map

Air Consumption: 0.3 m^3

Weight: 300kg

Dimension: 2200*1400*2300mm

Control: PLC,TOUCH,SCREEN

4 Nozzles Bottle Filling Machine

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Model: VK-EPF-4

Machine name: 4 nozzle bottle filling machine

Material: Stainless Steel

Capacity: 1000-1500 bph

Filling material: Flowing Liquid

Machine type: Automatic

Our Services

Training:

1. We offer machines training system, the customer can choose training in our factory or in customer workshop. The normal training days are 3-5 days.

2. We offer operation manual to customer.

3. We offer training video and machine operation video to customer.

4. We offer remote control service, if customer do not know how to operate and use the machine.

Installation:

We will dispatch engineers to carry out installation and debugging of the equipment in buyer's place if requested. The cost for International double ways air tickets, accommodations, food and transportations, medical shall be paid by Buyer for the engineers. Buyer shall fully cooperate with Supplier's engineer and make all the installation condition ready to work.

Warranty:

The Manufacturer shall guarantee the goods are made of Manufacturer's best materials. The sold machine will be guarantee in one year, in the guarantee year, any spare parts broken due to supplier's quality issue, the spare parts will be supplied free for customer, customer need to pay the freight cost if the parcel weight more than 500gram.