Cottage cheese is low in food energy compared to other types of cheese, making it popular among dieters and some health devotees. It can be used with a wide variety of foods such as yogurt, fruit, toast, granola, in salads, as a dip, and as a replacement for mayonnaise.

Cottage cheese is soft, white, and creamy. It's considered a fresh cheese, so it does not undergo an aging or ripening process to develop flavor. As a result, it has a very mild flavor compared with aged cheeses. Cottage cheese is made from the curds of various levels of pasteurized cow's milk, including nonfat, reduced fat, or regular milk.

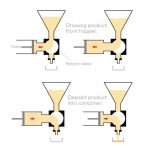

When you are bottling cottage cheese there are several types of filling machines you may choose.

VKPAK designs and builds filling machines and packaging equipment for cottage cheese.

Our machine is designed for the filling of cottage cheese in pre-formed plastic cups and containers of various shapes with sealing of pre-cut aluminum foil lids and capping with a plastic lid. The important point for filling cottage cheese is saving of cheese grain, high accuracy of dosing and high productivity.

The Production Of Cottage Cheese – Why?

1. Excellent profit. Cottage cheese is currently one of the most profitable products in the further processing of milk. Due to volume production, the profitability of semi and hard cheese production is currently low, but the profit for cottage cheese production is good. Factors that influence the better profitability of cottage cheese include the favorable competitive situation for special cheeses and better opportunities for the modification and branding of cheeses.

2. A fast and straightforward production process. Unlike the lengthy production and maturing processes of basic cheeses, the production process of cottage cheese is short and the cheese is packed straight into consumer packages without maturing. The production of cottage cheese is fast and the production process easier to manage.

3. The production line won’t take much space. A cottage cheese production line can often be placed within the existing premises of the cheese factory. This makes a cottage cheese production line a good expansion option for existing cheese factories.

All machinery suitable for: Cottage Cheese

Cottage Cheese Filling Machines

- Stable, reliable, safe, with alarm function.

- Variable frequency control, the filling time can be adjustable.

- The configuration elements adopt the international famous brand.

- High filling accuracy, suitable for all kinds of cups.

- Alarm and shutdown when gas supply is low.

- Easy to clean and maintenance.