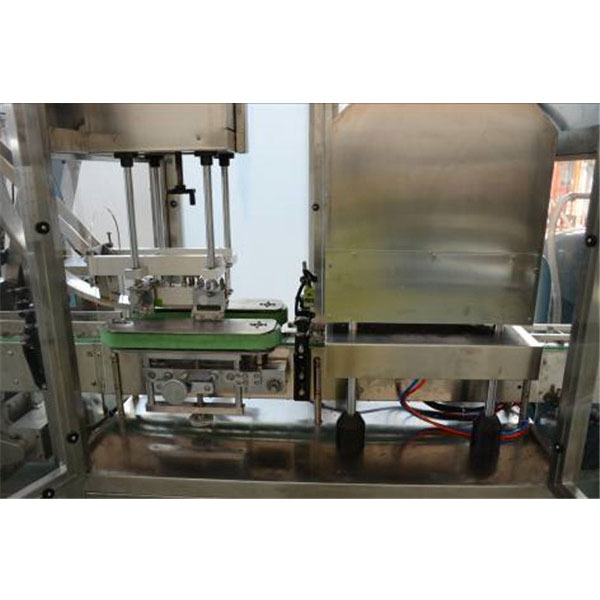

Automatic Twist Off Vacuum Capping Machine

This machine is researched and developed by our company with years of experience, it is unique in domestic .Integrated automatically cap arranging with covering, vacuum capping. Adopted manual vacuum pump to achieve high vacuum. With the functions of no bottle no covering, alarming when no caps are available. Enjoyed high automation. The main pneumatic and electric parts are from world famous brands. With stable and reliable performance. It is widely used for vacuum capping of the Glass Jars with iron caps in the industries of canned food, beverage, seasoning, health care products etc.

Suitable products for vacuum capping machine model:

The twist off cap vacuum capping machine for glass tin/can/jar the glass screw type cap,which uses the standard tinplate claw type thread cap. Such as the sauce,sea food can,fruit can,vegetable can, bean products can,etc.

Description

VKPAK is leading manufacturer of automatic twist off vacuum capping machine which is severing the wide range of industries like food, beverages and pickle manufacturing unit.The automatic twist off vacuum capping machine is capable of vacuum capping of the bottles with lug or twist-off caps as well as of those not necessarily to be vacuumed. The machine is applicable in wide range of industries like pickle unit, food, beverage and chemical sector. With its unique design & extensive scope of application, machine is intended for capping Glass bottles & caps in varied sizes only by simple adjustment instead of parts replacement.

The Unique feature of machine is "No Bottle - No Cap system" along with other features like compact design, smooth running, low noise, efficient energy consumption, simple operation, easy adjustment, maintenance and cleaning and higher degree of automation. The Automatic Twist off Cap Vacuum Lug Capping machine decreases air pressure inside a bottle by means of high-speed steam injection tightens the bottle cap & then vacuums the bottle by flushing cold water over bottle. The machine comes with unique vibrator feeder for cup and as a optional waterfall type cap feeder elevator also available.

Packaging Type: Cartons

Packaging Material: Wood

Type: Capping Machine

Condition: New

After-sales Service Provided: Free Spare Parts, Field maintenance and repair service, Video technical support, Overseas service center available, No after-sales service

Place of Origin: Shanghai, China

Brand Name: VKPAK

Voltage: 220V

Application: Food, Beverage, Commodity, Medical, Chemical

Weight: 850kg

Automatic Grade: Automatic

Driven Type: Electric

Dimension(L*W*H): 2100*900*1630mm

Model: VK-VC

Name: automatic Twist off vacuum capping machine

Product name: Cap Vacuum Capping Machine

Function: Auto Feeding Screwing Pressing Caps

Capping speed: 2200-2500 BPH

Material: SUS304/316

Keywords: Glass bottle capping machine

Size: 2100*900*1630mm

Technical Parameter

- Power: ≤2.3KW(including the vacuum pump)

- Production capacity: 2200-2500 BPH

- Cap diameter: ¢30-¢55mm ¢50-¢85mm

- Bottle height: 80-250mm

- Bottle diameter: ¢30-¢85mm

- Max vacuum: -0.08mpa

- Capping torsion: 5-20N.M

- Air consumption: 0.6M3/0.7Mpa

- Dimensions: about2100×900×1630mm 750X1060X1400mm

- Weight: about 850kg

Main Features:

This machine is researched and developed by our company with years of experience, it is unique in domestic .Integrated automatically cap arranging with covering, vacuum capping. Adopted manual vacuum pump to achieve high vacuum. With the functions of no bottle no covering, alarming when no caps are available. Enjoyed high automation. The main pneumatic and electric parts are from world famous brands. With stable and reliable performance. It is widely used for vacuum capping of the Glass Jars with iron caps in the industries of canned food, beverage, seasoning, health care products etc.

- 1).Integrated automatically cap arranging with covering and vacuum capping, with high automation.

- 2).Adopted manual vacuum pump to achieve high vacuum.

- 3).Capping torsion and vacuum degree can be set as required.

- 4).Suitable for different shapes and sizes bottles with changing few parts.

- 5).The main pneumatic and electric parts are from world famous brands to ensure stable, reliable and durable performance.