Automatic Laminated / Plastic / Aluminum Tube Filler And Sealer

The automatic tube filler and sealer is suitable for filling all kinds of semi-viscous and viscous products into plastic tubes. It can be used for pharmaceuticals, food products, cosmetics, and chemicals. Some of the products filled with this tube filler are ointments, lotions, caulks, adhesives, cheese spreads, and peanut butter. Tube feeding, filling, sealing, and finished product output are all conducted by a fully automated control system featuring Siemens touch screen technology. This tube filler/sealers offers quick adjustment, which makes it suitable for using multiple types of soft plastic and/or metal tubes.

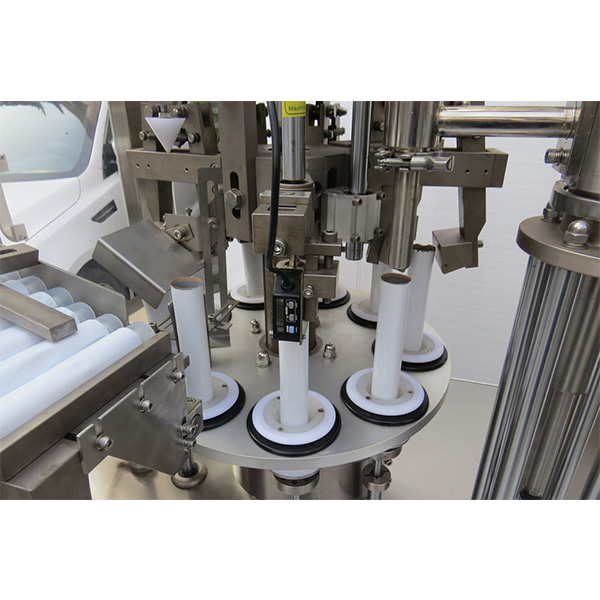

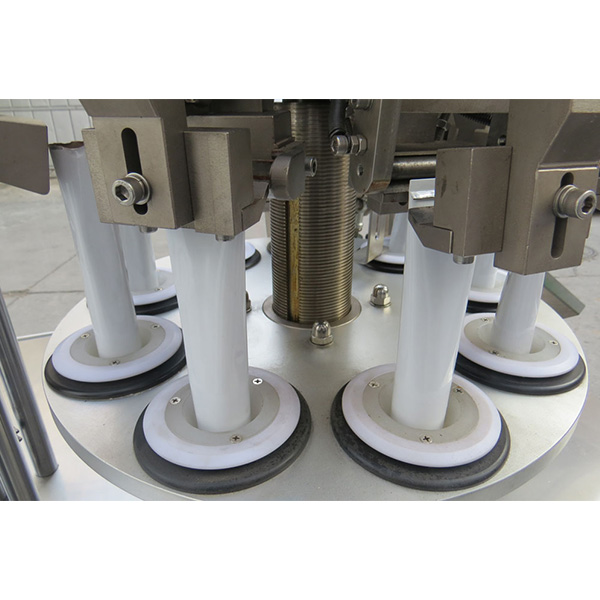

Tube Filling and Sealing Machines feed the tube into a rotary indexing table, orients the tube then fills and seals with either heat seal and trim, or fold and crimp for metal tubes. Suitable for a wide range of applications, tube filling and sealing equipment can fill creams, lotions, food products, pharmaceuticals, greases, gels, glues, pastes, and even, on occasion, powders. All of our automatic tube filling and sealing machines include automatic tube loading, orientation, filling, sealing, and coding for plastic or metal tubes with speed ranges from 30 to 80 tubes per minute and sizes up to 300 ml.

Description

It suits for filling, sealing and date printing the products adopting tube packing of daily chemistry, pharmacy, food and chemistry etc. industry, etc..

Automatically insert the tube and position, PLC control system ,heat the inner tube with hot air ,accurate position. Can adjust and show on touch screen the filling volume automatically, It is an ideal machine for sealing plastic tube for it is attractive appearance and reliability.

The machine was characterized by mechanism structure, stable operation, high speed, high efficiency, low noise, simple structure, convenient operation and maintenance and less fault.

Technical Parameters

- Filling volume: 5-300ml/unit (Adjustable)

- Filling accuracy: ≦±1﹪

- Capacity: 40-60unit/min, Adjustable

- Tube diameter: Φ10-50 mm

- Tube length: 50-200mm

- Hopper volume: 40L

- Power: 380V/220V (Optional)

- Air pressure: 0.4-0.6 MPa

- Equipped motor: 1.1KW

- Machine power: 5kw

- Inner wind motor: 0.37kw

- Convulsions motor: 0.37kw

- Dimension: 1950×760×1850(mm)

- Weight: About 750 Kg

Features

Level of automation of the tube filling machine:

The empty cosmetic tubes are loaded automatically. Subsequently, they are positioned, filled and sealed. The date or batch number is stamped on the seal. The tube filling and sealing machine removes end-products automatically.

Possible application of the automatic tube filling and sealing machine:

The automatic tube filler is used for packing of cosmetics, pharmaceuticals, chemicals and food products into tubes. The tube filling device is designed to handle large and medium size batches / production lots / jobs.

Key features of the tube filling and sealing machine:

- Compact Design

- Driving Parts Fully-closed

- Pneumatic Tube Washing & Feeding

- Intelligent Temperature Control and Cooling System

- Easy to Operate and Adjust

- 316L Stainless Steel Contact Parts to meet GMP Standard

- Safety Interlock Shutdown when Door is Open

- Overload Protection Provided

- Automated Working process from Tube Loading to Finished Products Output

- Automatic Orientation Effected by Photoelectric Induction

Optional Devices

- Chiller

- Date Coding Embossing

- Automatic Tube Feeding Magazine

- Change Parts

Basis of Design

The Tube Filling Machine shall be used for filling and sealing of tubes such as laminate tubes, aluminium and plastic tubes for semi-solid products.

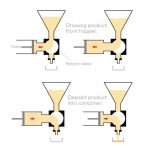

The Tube Filling Machine shall automatically operate to fill laminate tubes, aluminium tubes or plastic tubes with semi-solid products (Semi-solid products such as cream, gel, and ointment.) and seal the bottom of the tube with filled products with heat sealer or crimper. The tubes are manually fed to the tube feeder. A tube will be transferred via a single transfer chute and turned the bottom up. The tube is moved by rotation wheel to the dosing station. Semi-solid product prepared in the semi-solid manufacturing suite shall be transferred via a mobile vessel or vat and connected to the filling machine. Semi-solid products shall be supplied to the filling machine nozzle by vacuum or sanitary pump, as per the filling machine packaged skid design. The tube is filled with product with adjustable volume. Then the filled tube is moved to the seal station to seal the bottom of the tube whether heat sealer or laminate crimper. The sealed tube is conveyed out of the machine on the downstream by the transport system.

Advantages

High-grade LCD display programming controller and button combined operation screen, fully grasp the equipment’s stepless speed regulation, parameter equipment, production count statistics, air pressure indication, fault display and other operating conditions, making the operation simple and user-friendly.

Fully complete the whole process of human supply pipe, benchmarking, filling inert temperature body (optional), filling, sealing, coding, and finished product export.

High-precision benchmarking system reduces the range of color difference between the tube and the color scale.

External adjustment position and digital display of position, quick and accurate adjustment (suitable for multi-species, multi-species production).

Machine, light, electricity and gas integration, no tube is not filled, the tube is not in place, low pressure, automatic display (alarm); automatic function such as automatic shutdown when opening the protective door.