Automatic Bottle Air Washing Machine

It is an automatic bottle washing machine by air. the capacity depends on air washing nozzles.

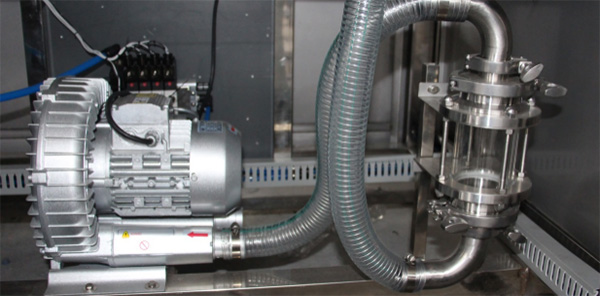

Air compressor transport the air inside the vacuum container, gas through the solenoid valve and the ion generator was been purified, the tracheal gas shampoo blow gas into bottles through the gas wash mouth, blow foreign out from gas wash mouth by the pressure of gas, back tracheal exhausted waste gas to the outside through emission control.

The machine is universal for glass bottle and plastic bottle rinsing with air. It adapts servo motor system for turning bottle up to down for air blowing and sucking. It can blow inside of bottle with clean air and sucking the dust out of the bottle.

Air Rinsers provide an efficient way to safely remove dust and small particles from containers before filling. This system is particularly suitable for removing loose contaminants that may have accumulated in the containers during shipping or storage. Containers first enter the rinsing area and are then bathed with ionized air generated by special transvector air flow amplifiers. The static charge that attracts debris to the surface of the containers is neutralized (ionized air does not sterilize the containers). Rinsing heads are lowered into the containers and a blast of compressed air is blown into them. A vacuum is then applied to remove the loose particulate. Debris is collected in a bag behind the machine or directed into the extraction system of the facility.

Description

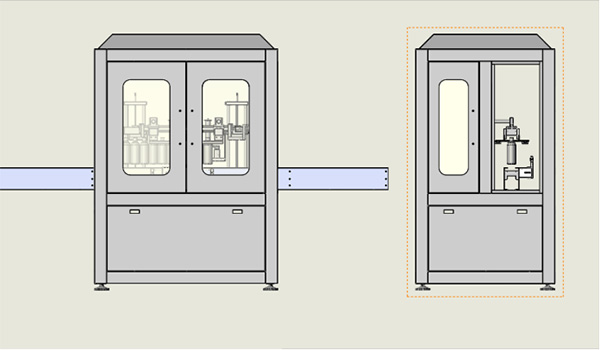

The automatic high speed bottle washing machine can work for many types of bottles at the same time. The new generation fast flipping bottle washing machines are designed for speedy production line, breaking through the old washing mode that allowed only one row bottles into washing machines. It washes at the same time with double rows of bottles by180-degree flipping bottle washing. When the machine is washing the first row bottles, the second row is conveyed to wait for the next washing. After finishing washing the first row, the second row will be immediately washed right after the first row outfeeds. The washing speed doubles by constantly flipping and washing bottles while still conveying and locating new bottles with no time wasted. We provide bottle water rinser and bottle air rinsers for different needs of products. The gas washing machin use powerful gas to inject into the containers directly, cleaning out the dust out of the bottles. It becomes an efficient bottle air washing machine, and bottle water washing machines use pure water to rinse.

High Efficient Automatic High Speed Bottle Washing Machine

The automatic high speed bottle washing machine can coordinate with the production needs to increase or decrease the number of nozzles. It can cleanse 16 bottles at most, and the size is arbitrary in the range allowed. Glass and plastic material bottles can also be washed at the same time. No machinery adjustment is needed when working with special bottle types, and they can be washed by customized fixtures. The automatic bottle washing machine is covered by a pharmaceutical grade transparent protective machinery structure, guaranteeing safely all sources of contamination during processes. It is suitable for the industries of food, pharmacy and biotech, which need production lines with high standard of bottle washing.

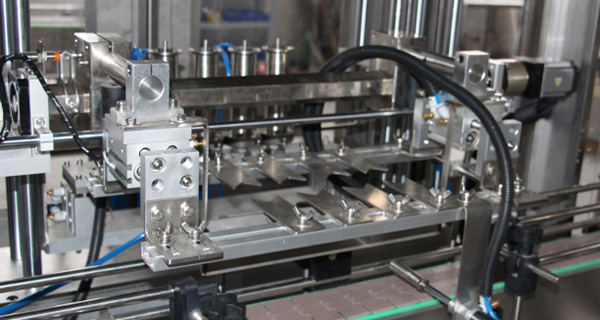

Bottle Clamping Device

It can clamp bottle mouth or body depending on bottle shapes and material.

Height adjustment with TBI screw leads

Blowing and sucking nozzles